News

News

Tel:

+86-799-6652759+86-0769-83517380-806

Mobile:

eva dai +86-18979985376

Vincene +86-15818417261

Irene +86-18273713863

QQ:

eva dai 2741947282

Vincene 2928711977

Irene 3094368671

Hollow coil paint covered wire coiling and coil, and has simple structure inductance of high precision, small distributed capacitance, high self resonant frequency, small temperature coefficient, good stability, strong anti-interference ability is a can be applied in the high frequency inductor.

The hollow coil can be used as current transformer, has bandwidth, small size, light weight, easy to measure, and the protection of the computer.Widely used in common mode filter, multi frequency transformer, impedance transformer, balance and unbalance converter transformer, suppression of EMI noise of electronic equipment, the USB line of personal computers and peripheral equipment, the liquid crystal display panel, low voltage differential signal, auto type remote control key and so on.

Hollow coil is widely used in the electronic products in daily, his role of electronic circuit is also very significant, so the use of its quality problems of electronic equipment, directly or indirectly affect the life or safety, so to control the factors that influence the quality of hollow coil. What are the factors that affect the hollow coil, we can calculate the inductance of the hollow coil:

Load the inductance of the press formula: the coil formula

Hollow inductance calculation formula: L (mH) = (0.08D.D.N.N) / (3D+9W+10H)

D------ coil diameter

N------ coil turns

D----- diameter

H---- coil height

W---- coil width

Units were mm and mH

From the calculation formula of the hollow coil inductance, it can be seen that the rational factor that affects the quality of the hollow coil is coil diameter, coil number, wire diameter, coil height, and coil width.. So when the hollow coil design appearance shape and size is determined, then a direct impact on the quality of hollow coil coil turns and wire diameter and the inner diameter of hollow coil, these factors have a direct impact on electrical parameters of hollow coil is in accordance with the inductance application conditions.

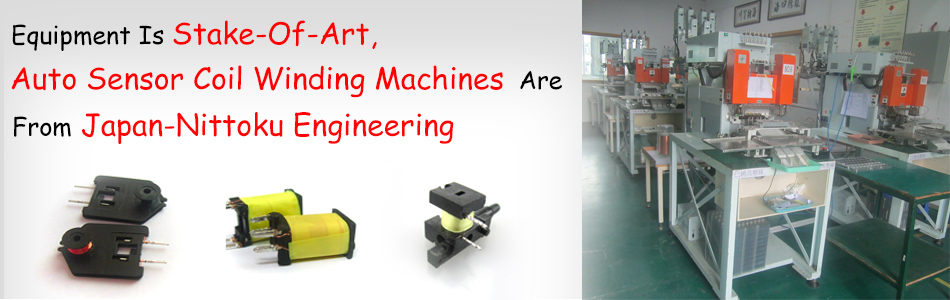

In addition to these, from the original state, there are wire material selection and precision of the mechanical equipment. According to the application condition and design scheme to determine the selection of raw materials, and the quality requirements of raw materials now from the previous 10 pinhole slowly to 0 pinhole development. This is because of the industry and customer of electronic product quality requirements more and more high. And the precision of mechanical equipment of precision directly affect the product, including: whether the deformation of the winding chaos, scratching, bad shape, convex line, face is not neat and so on, not only increase the product defective rate, to the qualified product is potentially dangerous, tend to directly affect the hollow coil and the service life of the electronic product safety, so quality of hollow coil products must use high precision manufacturing equipment.

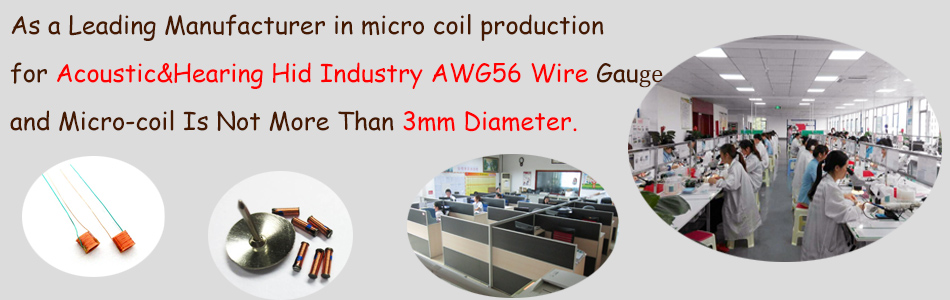

Dongguan Fuying Electronic Co., Ltd. in the inductive coil industry roll 25 years, good governance, constantly upgrading production line to expand production capacity, hollow coil winding machine line with the highest accuracy of Japanese imports of Rite Aid around the line machine, our product quality escort, for customers provide reliable guarantee.