News

News

Tel:

+86-799-6652759+86-0769-83517380-806

Mobile:

eva dai +86-18979985376

Vincene +86-15818417261

Irene +86-18273713863

QQ:

eva dai 2741947282

Vincene 2928711977

Irene 3094368671

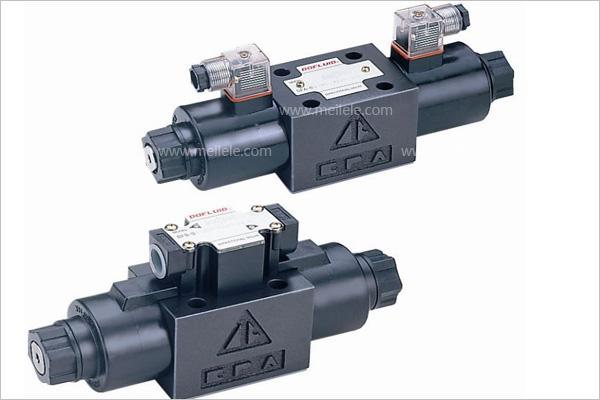

Hydraulic solenoid valve is a basic component in automatic flow control,to implement. Hydraulic solenoid valve used to control the direction ofhydraulic machinery and equipment factory activity, is generally controlled by the hydraulic cylinder, so it will use hydraulic solenoid valve.

Solenoid valve in a closed chamber, in different directions are provided with through holes, each hole is connected with the pipe cavity base isnot the same, the piston is two, double solenoid valve coil, the magnet coils body by controlling the signal interaction, to open or close the oil drain hole is not the same as with mobile control valve, and the oil inlet hole Shichang opened, hydraulic oil enters the oil outlet pipe is not the same, then the oil pressure to push the piston cylinder, piston andpiston rod piston rod of the femoral artery, femoral artery and mechanical gear. This control solenoid current on-off control of the mechanical movement.

From the principle of electromagnetic valve is divided into three categories:

Direct acting solenoid valve

Principle: power, the electromagnetic coil of electromagnetic attack force to lift off pieces, from the seat on the valve open; power, the electromagnetic force disappears, the spring pressure to close the file on the seat, the valve closed.

Features: in a vacuum, negative pressure, zero pressure can work, but the path is generally not more than 25mm.

Step direct acting solenoid valve

Principle: it is the principle of a direct acting and pilot combination, when the import and export no pressure, the power, the electromagnetic force directly to the pilot valve and main valve off pieces turn upward, open the valve. When the import and export reached the start pressure, the power,the electromagnetic force pilot valve, main valve chamber under increased pressure, the chamber pressure drops, and then use thepressure to push up the main valve; power, the pilot valve with a spring or to medium pressure to promote the closure of parts moving down, the valve closes.

Features: zero pressure or vacuum, high pressure can also be * action,but the power is larger, need to have the necessary level of equipment.

Pilot solenoid valve

Principle: power, the electromagnetic force to open the pilot hole, the chamber pressure sensitive decline, was closed around on the lower of high pressure, fluid pressure to promote the closure of parts moving up,the valve open; power, the spring force of the pilot hole closed, the inlet pressure chamber through the bypass valve off on Kong Lingmin arounda low on the high pressure, fluid pressure to promote the closure of parts moving down, close the valve.

Features: fluid pressure limit can be arbitrarily high planning, equipment(custom) but it is necessary to satisfy the conditions of fluid pressure.

2, solenoid valve from the valve structure and materials of the differenceis not the same as the principle, divided into six branch categories:diaphragm structure, step by step direct acting diaphragm structure, pilotdiaphragm structure, direct acting piston structure, direct acting piston structure step by step, the pilot piston direct drive structure.

3, solenoid valve in accordance with the function of classification: water solenoid valve, steam solenoid valve, solenoid valve, cryogenic solenoid valve, gas solenoid valve, solenoid valve, solenoid valve, ammonia gassolenoid valve, liquid solenoid valve, miniature electromagnetic valve,pulse electromagnetic valve, hydraulic solenoid valve normally open solenoid valve, oil solenoid valve, solenoid valve, DC high pressure solenoid valve, explosion-proof solenoid valve etc..

A hydraulic solenoid valve type, different manufacturers of different types of arrangement, such as 34BYM-L20H-T, which is 3 34 mark 4, B AC, Yhydraulic, M slide valve function of L marked the thread connection way,20, the nominal diameter, nominal pressure H, H standard for high voltage 31.5MPA, T marked the spring on the medium code. Want moredetailed type of meaning, can consult the relevant manufacturers.

1, by use of pressure control valve can be divided into relief valve,pressure relief valve and sequence valve.

(1): relief valve to control the hydraulic system at constant pressure toconstant. Overflow valve for overload protection is called safety valve,when the system pressure increases to attack weakness, may constitutethe limited value of damage, the valve will open the overflow, to ensure the safety of the system

(2) valve: the branch circuit to control the main loop than low oil wellpressure. According to the pressure relief valve function of its control is not the same, can be divided into constant pressure valve, differential pressure relief valve and proportional pressure reducing valve.

(3) sequence valve: to make an implementation of components in orderto make moves back, then other components implement action.

2, the flow control valve is the valve core and the valve body between thescheduling port area and its saving attack resistance for scheduling theflow, and then control the implementation of velocity components. By use of flow control valve is divided into 5 types.

(1): in the setting of saving saving valve orifice area, saving valve in the load pressure changes and motion even need not implement highvelocity components basically adhere to stable.

(2) control valve: to save valve import and export pressure is constantwhen the load pressure changes.

(3) shunt valve: regardless of load size can make the same oil source twoimplementation components are equal for the same amount of flow diversion valve or simultaneous valve; and be prorated for the proportion of flow diversion valve.

(4) collecting valve: it is the flow into the valve assembly distribution at therole of contrast with the shunt valve.

(5) shunt valve: both shunt valve and flow valve function.

3, divided into directional control valve by use of one-way valve and valve.

(1): only allows one-way valve one-way fluid in the pipe connected toreverse that is cut off.

(2): change is not the same as the valve pipeline between the on-offcontact, according to the spool in the valve in the working range numbertwo, three; the number of channels under the control of two, three, four,five pass through; according to the spool driving manual, electric motor,way, hydraulic.