News

News

Tel:

+86-799-6652759+86-0769-83517380-806

Mobile:

eva dai +86-18979985376

Vincene +86-15818417261

Irene +86-18273713863

QQ:

eva dai 2741947282

Vincene 2928711977

Irene 3094368671

A definition of the enameled wire (self-adhesive enameled wire & nonself-adhesive enameled wire):

Production of enameled wire is in the high purity, high conductivity of theconductor is covered with a layer of insulating coating, namely: conductorand insulation paint = non self-adhesive enameled wire

Conductor insulation paint layer + + = self-adhesive enameled wire

Two. The classification and structure of wire rod:

1 according to the conductor material can be divided into different:

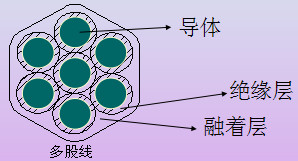

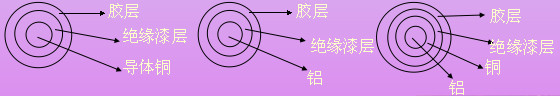

Copper (Copper), aluminum (AL), (C.C.A), copper clad aluminum wirestrands, as shown:

2 classification according to the thickness of insulating paint:

* if the CNS (Chinese national standard) or JIS (Japanese industrial standard) standard, the thickness of the insulation paint, can be divided into 0, 1, 2, 3 line, 0 line insulation paint thickness, 3 wire insulating paintthinner;

* if the IEC (International Electrotechnical Commission) standard, Grade1,Grade2, Grade3;

* if the NEMA (National Electrical Manufacturers Association) standard,Single.Heary.Triple.Type1.Type2. Type3

* due to different customers have different requirements, so the choice of different standard wire

Therefore, the decision must be carried out according to thecorresponding standard

3 according to the characteristics of insulating paint can be divided into:

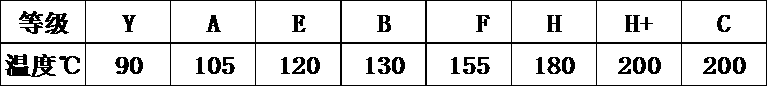

* PEI (poly imide polyester enameled wire), with Polyester-imide resin as the main body of the oil to the vast

Edge coating paint for the conductor; the heat level of 180 degrees C(grade H).

* UEW (polyurethane enamelled wire), with Polyester-thane resin as the main body of the oil

Insulating coating paint on the conductor and its characteristics; the maximum for soldering and thermal rating of 130 degrees (B).

* PEW (polyester enameled wire), with Polyester resin as the main oil asinsulating coating paint for conductor; the heat level 155 C (F) * AIW(poly imide enamelled wire), with Polyamide-imide resin as the main oil asinsulating coating paint for conductor and its heat resistance grade; 200 c (H+).

* SBUEW/SF.BW (self adhesive, direct welding enamelled wire) -- the biggest characteristic is in the heat or solvent action according to the jigshape can be glued into different shapes and can be directly solder,thermal rating of 130 degrees (B).

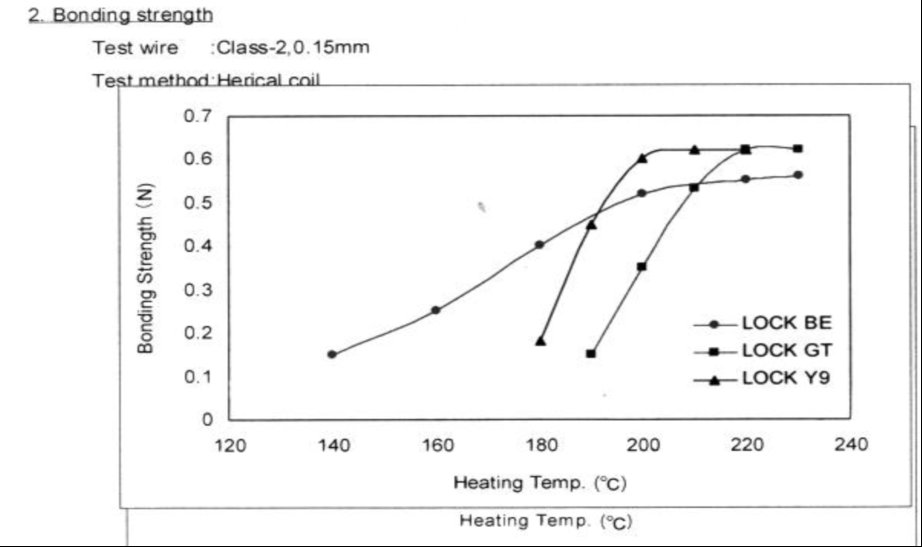

* Lock (solvent from the melting of polyurethane enamelled wire), theheat is 180 DEG -200 DEG (grade H-H+).

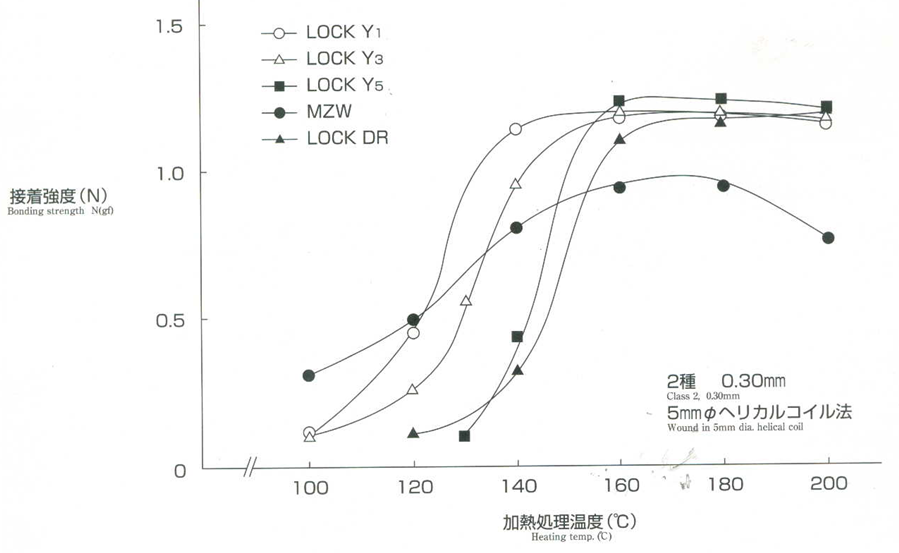

* Lock Y1/Y3/Y5 (hot melt type polyurethane enamelled wire) -temperature resistance is not the same, the resistance level by 140 DEG -180 DEG (grade -H).

4 according to the insulating paint heat level can be divided into:

5 according to the adhesive can be divided into:

Self - adhesive alcohol line under the influence of alcohol wire

The hot line, after the heat under the action of self bonding wire

Double wire bonding in alcohol or self - heat under the action of the wire.

Three identification of wire rod:

1 - "D": direct welding, which does not paint stripping can be directlysolder

2 - "Or R" - "N": R color, Red (red); N Nature (color);

3 + "B": the layer of the melt temperature of 130 DEG c;

4 + "N": coated nylon

5 - "L" / "CL" or "LS": low temperature solder

6 - "SL": the ultra low temperature solder

7 - "F": Or "H" F Or H, said the enameled wire.

8 "HT": the high tension wire.9.- "LZ": the wire.

Such as:

* 2 UEW + B------ 2 130 C polyurethane enamelled wire. 2 2 line B as atemperature of 130 DEG C. UEW insulating paint for polyurethaneenameled wire.

* 3 UEW - SL------3 for ultra low temperature solder polyurethaneenameled wire.

3 3 line SL for ultra low temperature solder UEW insulating paint forpolyurethane enamelled wire

* 2 DS - U P (H) ------2 solvent hot / hot air from the melting ofpolyurethane enameled wire.

2 to 2 lines of H into the P for hot melt way as solvent and hot air

U insulating paint for polyurethane enamelled wire DS for self brand name thaw resistance wire.

* LOCKHTW------ solvent type high tension wire

HTW is a high tension line Lock as a way for the solvent type

Four (1), temperature and viscosity of the control wire

(2) temperature and viscosity of the control wire

Five. Professional term wire 1 conductor diameter (Conductor Diameteror lnner diameter C.D or I.D. "), namely: bare copper conductor diameter.

2 diameter (Overall Diameter):

Abbreviation: O.D, that is, with the film and layer size, that is completely a thread size.

3 needle (PIN Hole): the film visual cannot distinguish between the holes

4 adhesive (Bond Strength): refers to the film and film making enameled wire using a solvent by heating or between the adhesive and can reach a certain requirement of 5 conductor resistance (Resistance): a conductor resistance testing machine, and then converted into a numerical representation of 20 degrees.

6 tagged Phi 0.25 Phi 0.027 Phi 0.161;; I.D (conductor diameter) is 0.25 mm; 0.027mm; 0.161mm; namely, that value is a conductor diameter size of the enameled wire.

Six. The inspection items and methods of wire (by JIS 3003:1999)

1, appearance: packaging packaging with moisture, securityrequirements; the outer box is complete, the entire shaft with a visual inspection of the identification and outside the box are the same, the spool is intact, arrangement is neat, no scars, dirt, self adhesive, color,grain etc.;

2 dimensions: measurement instrument with minimum scale 1/1000mm(but the size is 1/100mm number, is the effective number of bits to two decimal places, namely when) micrometer measurement; circular line: take 15cm long wire, 360. Each of the 120. The outside diameter, theaverage diameter is completed, and then use a lighter or caustic soda toremove paint, use the same method of test.

When the single point *1) specification is bad